Boron Nitride exists in various crystalline forms such as Hexagonal, Cubic and more. The hexagonal form is the most stable crystalline form of Boron Nitride. The chemical formula of Boron Nitride BN and its hexagonal form is hBN. hBNis commonly used as a lubricant.

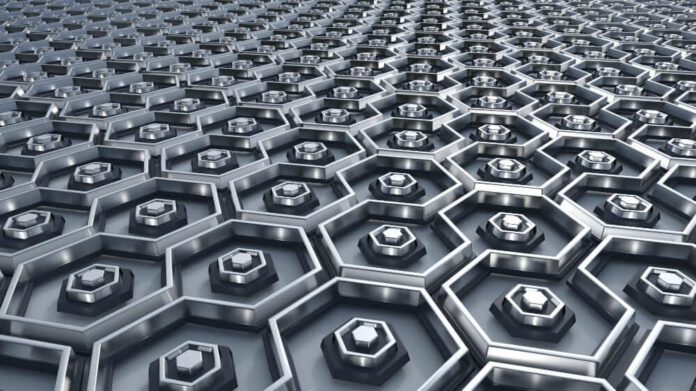

hBN has a lamellar structure similar to Graphite and is also known as White Graphite’. The layers are made up of Boron and Nitrogen atoms arranged in a hexagonal lattice. Within the layers the Boron and Nitrogen atoms are bonded with strong covalent bonds. The layers are held together by weak Van der Waals forces.

The easy shearing along the layers of hBN makes it a soft and lubrication material. The Hexagonal Boron Nitride monolayer is like Graphene and has a honeycomb lattice structure. hBN does not require the presence of water or gas molecules to act as a lubricant unlike Graphite.

Properties of hBN

- hBN can be used as a lubricant at both high and low temperatures even in an oxidising atmosphere. It can be used in place of Graphite for lubrication purposes. hBN has the ability to lubricate over a wide temperature range. It has a very high melting point of 2600° C.

- hBN has remarkable thermal and electrical stability. Because it has good thermal stability it can be used as a lubricant for engines. In such situations, Graphite would get oxidised and turn into Carbon sludge. hBN is an insulator which means it has a high electrical resistance and low dielectric constant.

- hBN can work effectively at temperatures up to 1000° C in air, 1400° C in vacuum and 2800° C in inert atmosphere. When used as a lubricant hBN is non-abrasive.

- hBN is non-toxic and chemically inert and it is not attacked by acids but is soluble in alkali molten salts and nitrides.

- hBN has low density and stability to thermal shock. As a thermal conductor it can be compared with stainless steel at cryogenic temperatures.

Applications of hBN

- When two surfaces move in reactive motion it leads to friction and wear. hBN can be used as a lubricant to reduce friction and wear. It can be easily sprayed or sprinkled on hot surfaces to provide dry lubricity.

- hBN can be used as a lubricant in applications that require vacuum. It is a good choice for space applications.

- Using liquid lubricants may require complex systems which have to be maintained. hBN is a dry lubricant which can be used easily and it is a ‘Clean lubricant’. It has a low shear resistance and can reduce friction by interacting with the sliding surfaces and forming boundary films. The formation of this tribofilm helps to avoid the contact between the moving surfaces and reduces wear.

- hBN is eco-friendly and it will not harm the environment. Liquid lubricants can be difficult to recycle after use and may harm the environment. It can be used as an additive for lubrication in green technologies.

- hBN can be added to lubricating oils and greases to improve their lubricating properties. hBN can be dispersed in oil, grease or water for lubrication in high-temperature and high-pressure applications.

Synthesis of hBN

hBN can be produced using top-down and bottom-up methods. The top methods are mechanical exfoliation and chemical exfoliation. The bottom-up methods are chemical vapour deposition and physical vapour deposition.

Top-down methods

Mechanical exfoliation

In this method the regular adhesive tape is used to create hBN sheets. The atomic sheets of hBN are physically pulled and separated from each other. The yields can be small but the number of defects on the sheets are less compared to other methods.

Chemical exfoliation

This process is carried out using liquid solvents. The sonication process is used to break the Van der Waals forces thus allowing the solvent molecules to expand the atomic layers. This process can give a higher yield but the output can get contaminated easily.

Bottom-up methods

Chemical vapour deposition

In this process the substrate is exposed to precursors which react on the surface to produce the hBN film. Solid, liquid or gaseous precursors can be used. The process can be carried out in atmospheric pressure, low pressure and ultra-high vacuum. However, this process can lead to toxic byproducts.

Physical vapour deposition

The processes that can be used are spluttering and co-segregation. In spluttering the target is bombarded with energetic particles to form a hBN film. In the co-segregation process a source of Boron and Nitrogen is sandwiched between Co/Ni film and SiO2. A thin atomic layer of hBN can be created by annealing the structure in a vacuum.