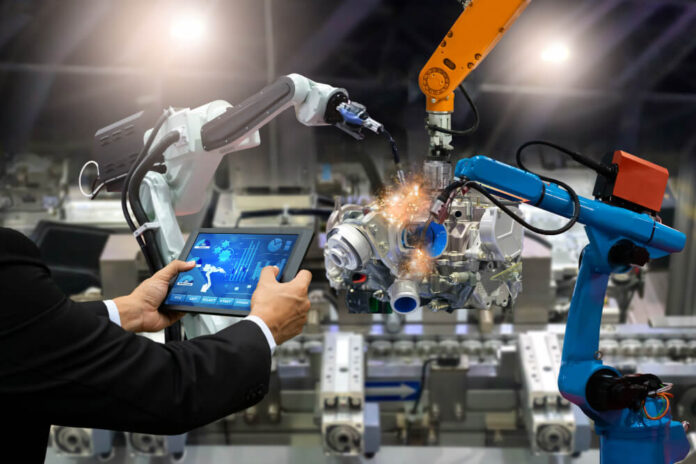

Machine-tending robots have emerged as a transformative technology in the field of manufacturing. These automated systems play a crucial role in enhancing productivity, efficiency, and precision in various industrial processes.

By streamlining manufacturing operations, the robots offer potential solutions to address the challenges faced by the industry. In this article, we will be taking a closer look at the significance of machine-tending robots and their impact on revolutionizing manufacturing practices.

We will discuss how these advanced robotic systems are leading the way toward a future where automation plays a central role in shaping the manufacturing sector.

How Is Machine-Tending Robots Revolutionizing Manufacturing?

#1: Helps in Increasing Productivity

Machine-tending robots play a pivotal role in enhancing productivity within the manufacturing industry. These robots are designed to automate repetitive tasks involved in machine operation, such as loading and unloading parts, tool changes, and quality checks.

By improving automation, they eliminate the need for human intervention in these processes, reducing the risks associated with manual labor and increasing overall efficiency. These robots are equipped with precise programming and advanced sensors, making it easy for them to perform tasks with high accuracy and consistency, minimizing errors and rework.

Additionally, by reducing downtime caused by human fatigue or errors, machine-tending robots ensure continuous production flow, leading to increased output and reduced costs.

#2: Enhances Efficiency and Precision

Machine-tending robots are masters of precision. They can carry out tasks with incredible accuracy, consistently delivering quality results. Unlike humans, who may tire, get distracted, or experience variations in their performance, robots maintain their precision throughout their operation.

This level of accuracy reduces the likelihood of defects in products, minimizing waste and the need for rework, ultimately saving time and resources.

Furthermore, these robots can handle delicate materials and components with utmost care, preventing damage that could occur during human handling.

They are equipped with advanced sensors and vision systems that enable them to adapt to changes in the manufacturing process, ensuring that tasks are executed with unwavering precision.

#3: Streamlining Manufacturing Processes

Machine tending robots are not just limited to automating repetitive tasks; they play a crucial role in streamlining the entire manufacturing process.

By taking care of tasks like loading and unloading materials, changing tools, or transporting parts, these robots allow human workers to concentrate on more complex, value-added activities. This division of labor optimizes the workflow, leading to smoother operations and shorter production cycles.

Apart from that, machine-tending robots can also be integrated into existing production lines without requiring major overhauls. Their flexibility in adapting to different tasks makes them versatile assets in various industries, from automotive manufacturing to food processing.

This flexibility means that manufacturers can respond quickly to changing market demands or product variations without significant downtime, keeping their operations agile and adaptable.

#4: Makes it easy to Overcome Challenges in Manufacturing

Manufacturing often faces challenges like labor shortages, the need for skilled workers, or coping with unexpected surges in demand. Machine tending robots are a versatile solution to address these challenges.

They don’t demand extensive training, and they can be reprogrammed or redeployed to different tasks as needed. This adaptability makes them valuable assets in times of change.

Moreover, these robots can work alongside human operators, augmenting the existing workforce rather than replacing it. They collaborate seamlessly, combining the strengths of both human creativity and robotic precision.

This synergy empowers manufacturers to meet evolving demands and navigate the complexities of modern production while maintaining high standards of quality and efficiency.

The Future of Manufacturing: Machine-Tending Robots Leading the Way

Advancements in technology continue to shape the future of the manufacturing industry, with a particular focus on the implementation of robotic systems that streamline processes and enhance productivity.

Automation is a key aspect of this transformation, leading to concerns about job displacement. However, studies have shown that while some jobs may be eliminated or changed due to automation, new employment opportunities are also created.

Machine-tending robots play a significant role in this evolution by taking over repetitive and mundane tasks previously performed by humans. This not only improves efficiency but also reduces the risk of human error and increases overall safety in manufacturing operations.

Moreover, machine-tending robots offer cost effectiveness through increased production speed and reduced labor costs. The return on investment (ROI) for these robots can often be achieved within a short period due to their ability to operate continuously without breaks or fatigue.