The packaging industry has many fields that work with different products. Needless to say, no matter the industry, there is a need for adequate equipment if the business wants to succeed. With the food industry being worth billions of dollars, there is little room for mistakes. Everything needs to run as smoothly as clockwork to be successful. Additionally, the food industry must meet one of the highest sanitary requirements as well as quality checks. This is all possible with modern machinery as it is designed to be fast and reliable. Packaging machinery is not something a business can simply ignore. Without it, the business can never compete with other businesses in the industry. Every packaging machine has certain features that contribute to the business. Whether it is automation, ease of use, reliability, or even data collection, everything is equally important.

In this article, we will talk about 5 important features of food packaging machines that you can expect the majority of machines to have and more. If you are ready, read on to get started.

Reliability and Quality

The most important thing you want out of your machine is reliability. A machine that you can rely on is the backbone of your business. Therefore, food packaging machines are built from quality materials and are made to last. This is because the machine needs to work whenever you need it without fail. If the machine is unreliable, that will just put a wrench in your daily plans and will only slow down your production rather than improve it. With modern food packaging machines, you have nothing to worry about. It can handle both high and low-volume jobs accordingly. If necessary, the machine can handle a large amount of product demand without the need for breaks or pauses. As we said, these machines are made to last so you can rest assured that you have a solid machine for years to come.

Product Safety

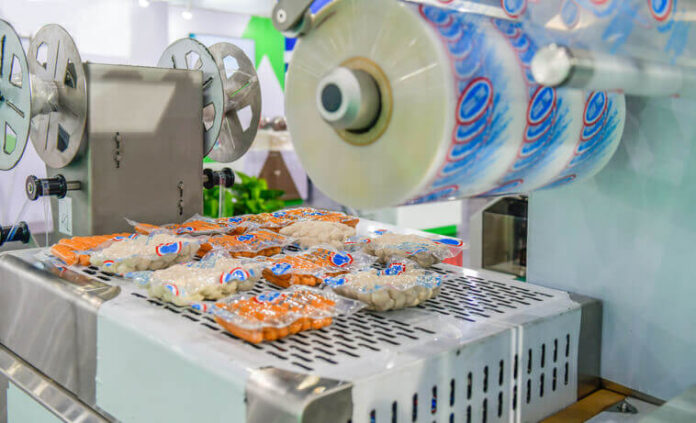

As the food industry progressed, more and more emphasis was put on the safety of the products. Every business needs to keep up with sanitary requirements if they wish to continue working. Handling food manually by hand is not something that should be done in today’s industry. This way, the possibility of contamination is extremely high. However, with the use of packaging machines, the possibility of contamination is almost nonexistent. With minimal human contact, the food remains in a sanitary environment until they are packaged and ready to transport. For example, with the use of overflow filling machines products that require preserving liquids can easily be filled without worry that the container will get contaminated.

That being said, even though there is still an extremely small possibility of cross-contamination, with the help of these machines, your business will certainly provide safe products to the clients.

Automatic

Another great feature that comes with food packaging machines is the level of automation they provide. Depending on what level your business is at, you can always find a machine that will suit your needs. If you have a small business that does not have a large product demand, you can probably settle for a machine that does not have a particularly large output. That being said, as your business progresses, you can upgrade your machine as it is needed. Automatic packaging machines can do the majority of the packaging process on their own. With proper input settings and minor changes, as it is needed, you will have a machine da will work nonstop without any problems. This will increase your product output as well as the quality of your product.

Lower Costs

Even though these machines can get pretty expensive, they will definitely reduce your costs and save you money in the long run. With the implementation of an automatic filling machine, you will see a significant reduction in your expenses. Finding the necessary amount of workers that are willing to work for a long time can be difficult. You will constantly have to worry about workers quitting and how to replace them. During that time, your business will only lose efficiency and in the end, lose you money. With a packaging machine, you will not have to worry about that. The only thing you will have to do is train your staff to operate the machine. This is much cheaper compared to the training process of a new worker to work on the production line.

Collecting Data

The newer generations of packaging machines come with different systems that can track and collect data regarding the working process. This includes product output, how many resources are used, performance, pressure, or any other useful information you might need. This way you can easily see where the problems are, why the production is slowing down, or see if there is an unnecessary waste of product or energy.